News

03/04/21 - 07:00

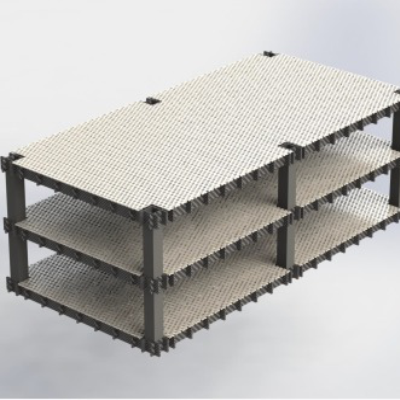

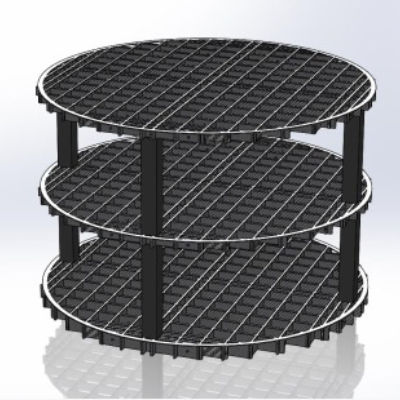

LMTerm designs and supplies bespoke CFRC grids and devices

LMTerm designs, develops, and manufactures CFRC (Carbon Fiber Reinforced Carbon) grids and devices for vacuum furnaces dedicated to industry segments such as mechanical metal, automotive, solar, semiconductor, aeronautical, aerospace, mining, heat treatment in general, among others. Projects are designed and simulated according to the needs and applications of each customer.

Among the benefits of CRFC is the low thermal load, which allows for faster heating and cooling and energy reduction during each cycle. On the other hand, the load capacity is more significant, which allows for improved productivity. Besides, the system is modular, allowing the repair of individual parts in case of damage.

The grids and devices are lightweight and reduce the risk of handling accidents. In addition, mechanical strength increases with the temperature, and there is an improvement in the quality and result of the treatment with a precise loading arrangement.

The system has high stability and resistance to thermal shock (no deformation) and is not susceptible to fatigue. In addition, design is customized for specific applications and process optimization, leading to a significant increase in service life.

The grids are for multi-level vertical and horizontal furnaces, ceramic insulation, or even the modern Whipox.

MORE – LMTerm also produces unique pieces with graphite, molybdenum, and tungsten. Among other items, the following items are available: vacuum seals, pneurop/KF vacuum connections, instrumentation, valves and actuators, ceramics, thermocouples, fluids, and oils.

The grids and devices are lightweight and reduce the risk of handling accidents. In addition, mechanical strength increases with the temperature, and there is an improvement in the quality and result of the treatment with a precise loading arrangement.

The system has high stability and resistance to thermal shock (no deformation) and is not susceptible to fatigue. In addition, design is customized for specific applications and process optimization, leading to a significant increase in service life.

The grids are for multi-level vertical and horizontal furnaces, ceramic insulation, or even the modern Whipox.

MORE – LMTerm also produces unique pieces with graphite, molybdenum, and tungsten. Among other items, the following items are available: vacuum seals, pneurop/KF vacuum connections, instrumentation, valves and actuators, ceramics, thermocouples, fluids, and oils.