TEMPERATURES RANGING FROM 50°C TO 2000°C

High-performance furnace and systems for diverse and demanding applications ranging from production to research

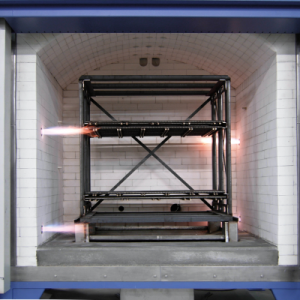

A vast array of standard furnaces with electric, gas, or bespoke heating

Efficiency, productivity, low operating and maintenance costs are the hallmarks of the industrial furnaces developed and marketed by LMTerm through the German ThermConcept. The equipment serves industries such as heat treatment, ceramics, glass, laboratories, foundry, plastics and composites, cutlery, automotive, aeronautics, and aerospace.

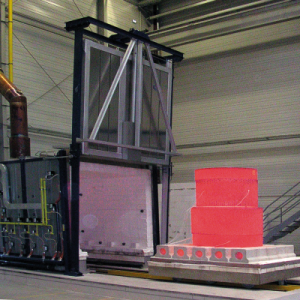

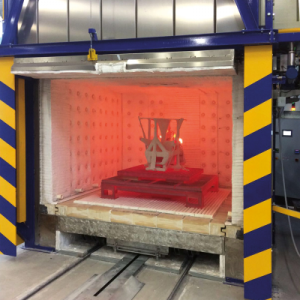

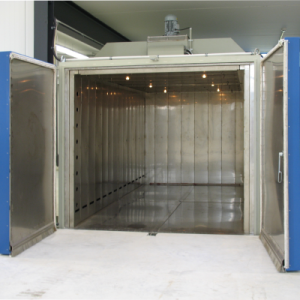

The furnaces can be horizontal, vertical, mobile hearth, tubular, chamber, well, retort, tilting crucible, among others. Moreover, they can be heated by electrical resistance or even gas combustion, being configured from 50 ºC to 2000 ºC, and can have a controlled atmosphere or not.

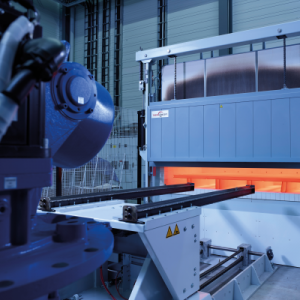

The equipment can be of simple control or with PLC and complete automation, with SCADA software, integration with the production line, automatic loading and unloading, management of volatiles and residues burned in the process, and much more.

This equipment is widely applied to processes such as quenching, tempering, stress relief, normalizing, burning, debinding, sintering, calcining, gluing, molding, vulcanizing, drying, testing, heating, melting, among others.

This equipment is widely applied to processes such as quenching, tempering, stress relief, normalizing, burning, debinding, sintering, calcining, gluing, molding, vulcanizing, drying, testing, heating, melting, among others.