HARDNESS AND RESISTANCE

Dedicated equipment with diverse solutions for applications that demand maximum performance

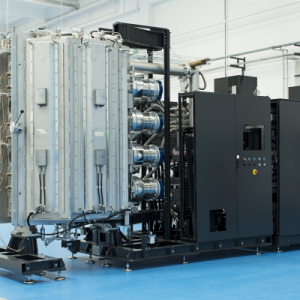

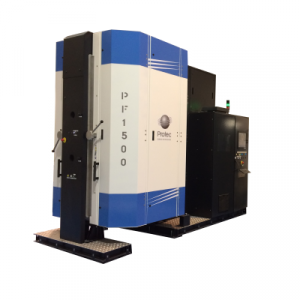

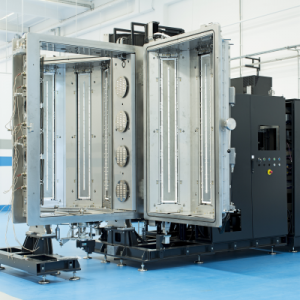

In partnership with the Italian company Protec, LMTerm designs, develops, and markets complete solutions in PVD and PECVD equipment to deposition thin films, both decorative and technical. The processes are innovative, and the equipment has characteristics that allow competitive technical solutions based on specific customer needs.

For the technical area, coatings are for functional applications (tribological or tool) for different metals and usually have a thickness ranging from 1 to 6 microns. The machines offer fast processes and excellent application, with low operating costs.

The main objective of these coatings is to increase the work performance and operational resistance of the parts. Functional coatings are successfully used in various fields because of their high hardness, good adhesion to the substrate, corrosion resistance, in addition to low coefficient of friction.

Para a área técnica, os revestimentos são para aplicações funcionais (tribológicas ou de ferramentas), para diferentes tipos de metais e usualmente têm espessura que varia de 1 a 6 microns. As máquinas oferecem processos rápidos e excelente aplicação, com baixo custo operacional.

O objetivo principal destes revestimentos é aumentar as performances de trabalho e a resistência operacional das peças. Revestimentos funcionais são utilizados com êxito em vários campos por conta da elevada dureza, boa adesão ao substrato, resistência à corrosão, além do baixo coeficiente de atrito.

Typical coatings are: TiN, AlTiN, AlCrN, TiAIN, TiCN, CrN, ZrN, DLC. The diamond-like carbon (DLC) coating family can be conducted using PVD or PECVD technology. DLC is an innovative coating family with high sp3 carbon bonds (like a diamond). The most common DLC coating is metal-doped DLC (Me-DLC), obtained using magnetic spray technology. Protec has recently developed the next generation of DLC (aC:H) coatings using PECVD Plasma Beam Source (PBS) technology. Thanks to PBS, DLC coatings are less expensive and perform better.

Many industries, typically on engine components (injections, piston rings, and pins, valves), primarily for friction reduction, use DLC coatings. Other important characteristics are hardness and good resistance in corrosive environments.

LMTerm offers different DLC solutions depending on the application. In addition, other carbon-based coatings can be provided as hydrogen-free DLC coating (ta-C) and amorphous carbon (aC) deposited using magnetic spray technology.

ABACO®️ – Protec has ABACO®️ (AntiBActerial COating), the first and most advanced nanometric PVD Bactericidal and Virucidal coating on the market, which fulfill both decorative and functional purposes.

ABACO®️ can be applied as decoration on doorknobs, bathroom metals, cutlery, domestic utensils, and any other metal as desired. These thin PVD films destroy bacteria and act continuously throughout the life of the object. Thus, the technology also has application to countless objects and surfaces.

The ABACO®️ finish is also hypoallergenic and does not leave aesthetics aside: hardness, high color stability, and scratch resistance. In addition, it can be applied to both ferrous and non-ferrous metals.

In 2021 it was validated after tests carried out by the Institute of Biology of the State University of Campinas (Unicamp). In addition to being bactericidal, the coating is also effective against Coronavirus. The technology was tested to be effective against virus strains like the Coronavirus MHV, Betacoronavirus genera (same genera and family as SARS-CoV-1, SARS-CoV-2 / COVID19, and MERS). The tests followed the international standard ISO-BS ISO 21702: 2019 (first edition 2019-05-27).

Typical coatings are: TiN, AlTiN, AlCrN, TiAIN, TiCN, CrN, ZrN, DLC. The diamond-like carbon (DLC) coating family can be conducted using PVD or PECVD technology. DLC is an innovative coating family with high sp3 carbon bonds (like a diamond). The most common DLC coating is metal-doped DLC (Me-DLC), obtained using magnetic spray technology. Protec has recently developed the next generation of DLC (aC:H) coatings using PECVD Plasma Beam Source (PBS) technology. Thanks to PBS, DLC coatings are less expensive and perform better.

Many industries, typically on engine components (injections, piston rings, and pins, valves), primarily for friction reduction, use DLC coatings. Other important characteristics are hardness and good resistance in corrosive environments.

LMTerm offers different DLC solutions depending on the application. In addition, other carbon-based coatings can be provided as hydrogen-free DLC coating (ta-C) and amorphous carbon (aC) deposited using magnetic spray technology.

ABACO®️ – Protec has ABACO®️ (AntiBActerial COating), the first and most advanced nanometric PVD Bactericidal and Virucidal coating on the market, which fulfill both decorative and functional purposes.

ABACO®️ can be applied as decoration on doorknobs, bathroom metals, cutlery, domestic utensils, and any other metal as desired. These thin PVD films destroy bacteria and act continuously throughout the life of the object. Thus, the technology also has application to countless objects and surfaces.

The ABACO®️ finish is also hypoallergenic and does not leave aesthetics aside: hardness, high color stability, and scratch resistance. In addition, it can be applied to both ferrous and non-ferrous metals.

In 2021 it was validated after tests carried out by the Institute of Biology of the State University of Campinas (Unicamp). In addition to being bactericidal, the coating is also effective against Coronavirus. The technology was tested to be effective against virus strains like the Coronavirus MHV, Betacoronavirus genera (same genera and family as SARS-CoV-1, SARS-CoV-2 / COVID19, and MERS). The tests followed the international standard ISO-BS ISO 21702: 2019 (first edition 2019-05-27).